SCOTT & WHITE CENTRAL UTILITIES PLANT

Provided mechanical engineering design for a new central plant to support over 2 million square feet of hospital campus. The plant design incorporates 10,500 tons of chiller capacity and 3,500 BHP of steam boiler capacity. Additionally, the central plant is capable of supplying medical oxygen, nitrogen, nitrous oxide, and carbon dioxide to the entire hospital campus. The central plant has wide temperature difference, variable primary flow chillers with heat recovery condensers for energy efficiency. The boilers have high efficiency burners for additional energy efficiency. The total cost of the project is $19 million.

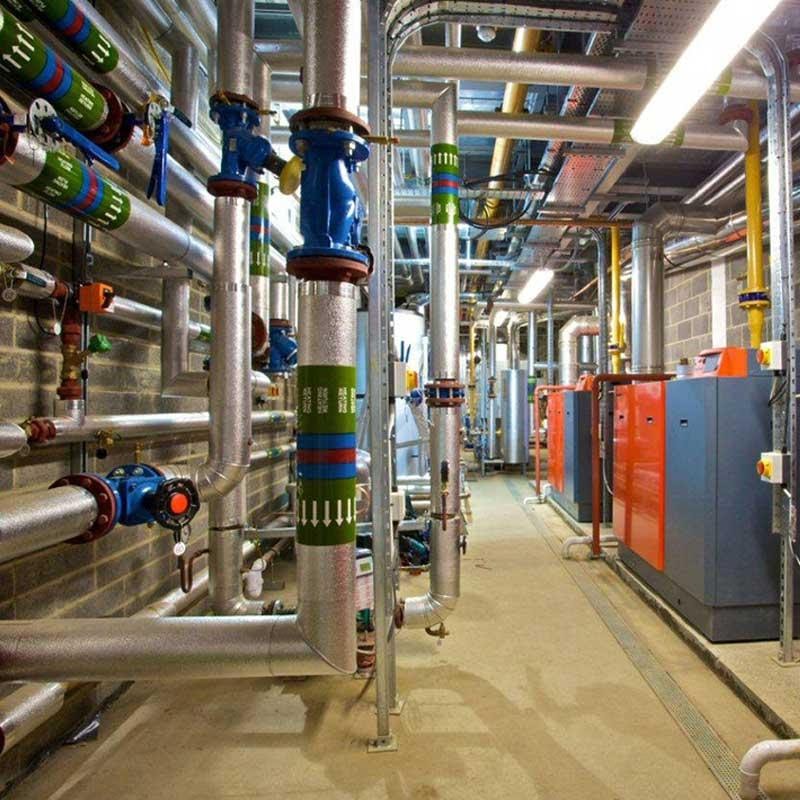

UNITED HEALTHCARE CENTRAL PLANT REMODEL

Provided project management and mechanical engineering for the renovation of the central plant that increased the chiller capacity from 1,200 tons to 2,250 tons and the boiler capacity from 500 BHP to 750 BHP. The chiller plant was converted from a constant volume system to a primary-secondary variable flow system. Also, the chiller and boiler systems were outfitted with electronic DDC controls.

DECATUR, TEXAS

WISE REGIONAL HEALTHCARE SYSTEM

Designed a new central plant to support a new 168,000 ft2 hospital. Systems included a chilled water plant, steam boiler plant, medical gas yard, emergency power system, and water treatment system. System utilized a "primary secondary" variable pumping system.